Assistant Professor Brian Plouffe received a unique summer project assignment this year. With a new 3-D printer in the Watson-Hubbard Science Center, Plouffe was asked if he could print as many face shields as possible for Regis College health sciences students’ PPE supplies.

“I said I could certainly try,” said Plouffe, the founder and undergraduate director of the biomedical engineering program. “I was fortunate to have all the material I could ever need to make face shields and I was more than happy to support the School of Health Sciences.”

Plouffe’s assignment came from Laura Burke, dean of the School of Health Sciences, and Kathryn Edney, dean of the School of Arts and Sciences. The face shields were distributed to diagnostic medical sonographer students, occupational therapy students, and others in the health sciences programs.

“I am truly proud of the collaboration this summer between the School of Arts and Sciences and the School of Health Sciences,” said Edney. “The work that Dr. Plouffe is doing exemplifies everything that Regis stands for, as well as the value of interdisciplinary thinking, especially during these unprecedented times."

A 3-D printing novice, Plouffe said he went through three different design templates before he found the one he felt worked best. The shields are made of polylactic acid, one of the most common materials used in 3-D printing. Plouffe was able to print about 30 face shields over the summer. It took about three to four hours to make one face shield.

“I come from more of a chemistry background,” Plouffe said of his learning curve. “But there is a lot of information out there and readily available.”

When it is not creating face shields, Plouffe said the 3-D printer will be used by biomedical engineering students for their senior-year final project, which includes working with doctors, patients, and other end users in the health care industry to develop solutions to challenges they are facing.

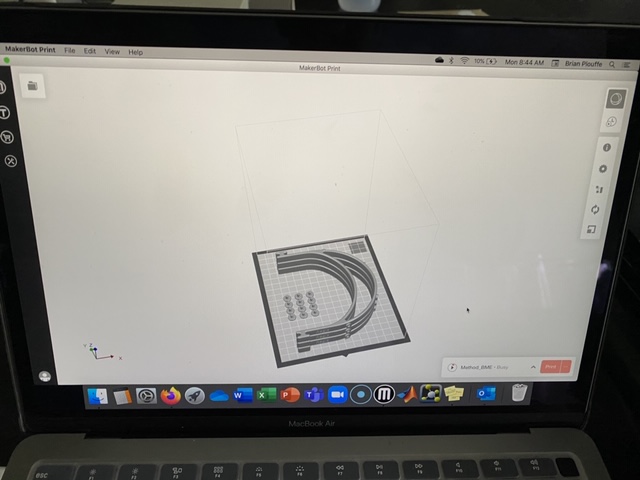

Designing the Masks

Assistant Professor Brian Plouffe used a 3-D printer to make face shields for students in the School of Health Services.

Printing the Masks

Each mask took about three to four hours to print.

The Final Product

Prof. Plouffe made about 30 face shields this summer.